GaiaStage commits to the use of recycled and recyclable materials. We support the idea of the creative commons: We invite people all over the world to copy our designs, blueprints and ideas, and to build their own GaiaStage!

We are also aware that the carbon footprint of audio amplification and light-shows are a small percentage of the overall carbon-footprint of a typical festival event. But by primarily organising grass-root events with local performers and encouraging the audience to travel to the event by bicycle, on foot and/or public transport, we raise awareness for such implications and related challenges in the music industry.

The generator-stations are customised exercise bike-stands. They ship with an adjustable magnetic brake which we replace by a DC motor. See the videos of the working prototypes we have built below.

The GaiaStage Generator Station provides energy for the use of lights and audio amplifications on Gaia Stage. As a proof of concept, we connected audio equipment directly to the generator, on the one hand to show what sound pressure levels are possible to achieve by one person pedalling and on the other hand to inform on the need for buffer storage.

The Stands we use, ship with an adjustable magnetic brake. This brake is replaced by the DC motor via an axle coupling. The stand takes a range of bicycle wheel sizes, from approx. 16-29” wheels.

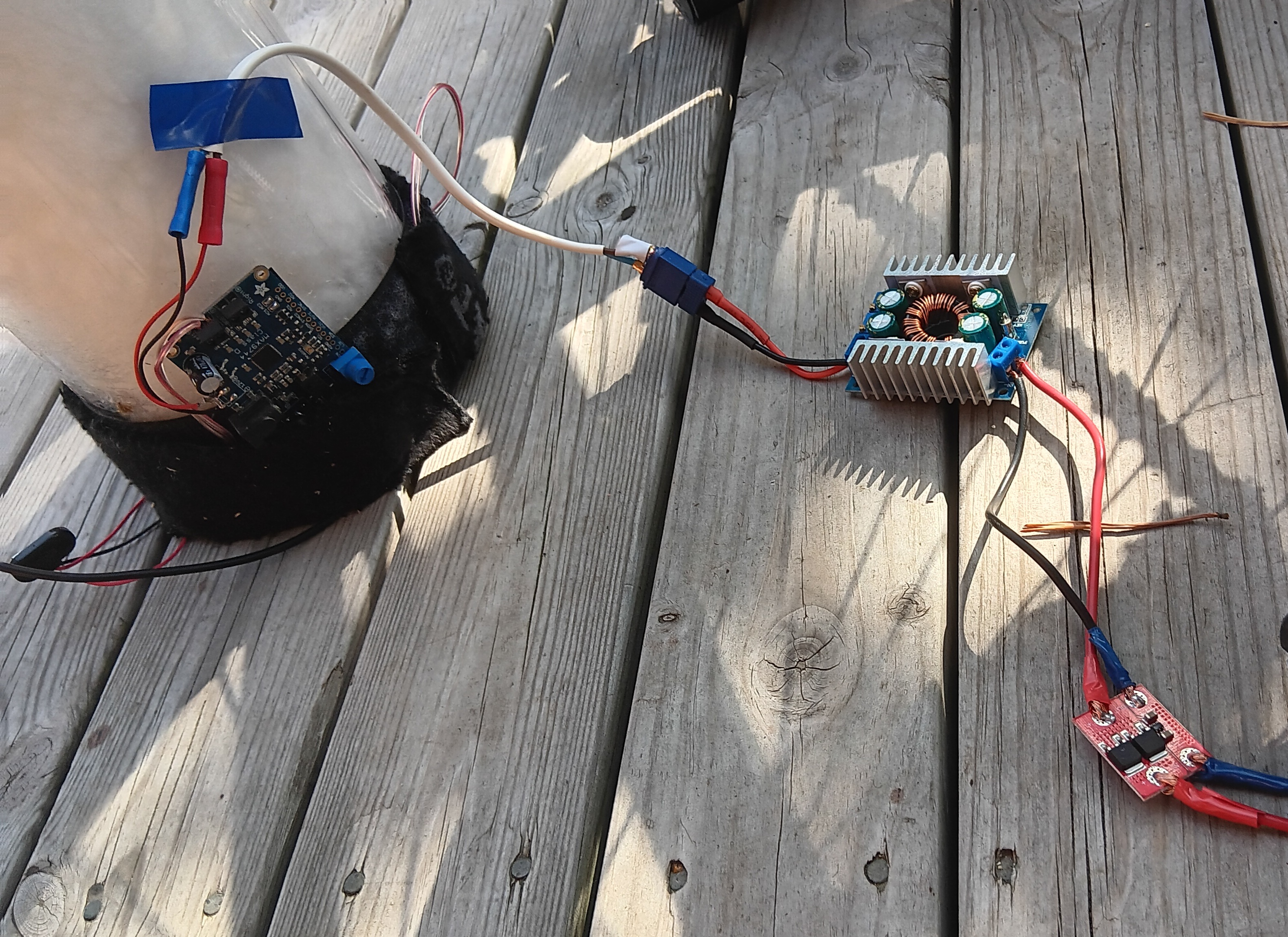

The Generator is a brushless 24V 116W DC universal motor (generator/ motor) with a 7mm ø axle connected via a sleeve coupling to the 10mm ø axle of the stand’s spindle. The motor’s rpm rating is 4430, the spindle is approx. 30 mm, the bicycle wheel 622 mm. Ideally, the bicycle wheel would need to rotate at 200 rpm. (This is high: averagely we pedal @ 80-100 rpm)

The Direct Current for both experiments passes through an ideal diode, avoiding polarity reversal, and the through a buck-boost regulator, which allows for adjustment of the voltage anywhere between 5-35 V. For the boombox, we set it to 9V, for the inverter, to 13V

Power For 9V Boombox: The boombox consists of a 12V car-audio speaker and a class D amp. The sound pressure levels achieved were not measured, but experienced as sufficiently loud for the size of speaker and the location in a residential area. There was no discernible effort needed to keep the system running. The systems rotational inertia was also able to buffer some energy, allowing for pedalling-pauses of a few seconds without the sound interrupting. See it in action here

The axle coupling and mounting of the generator is rather noisy, probably though suboptimal fitting: The non-standard axle diameter of 7mm needed shimming to fit into the 8mm-10mm adapter. A more professional mounting is needed to reduce noise.

Power For Standard 230V Equipment Audio amplifiers require DC current as a constant reference voltage to generate an (AC) audio signal. To run the Genelec 1029A active speakers, we converted DC first to 230V. Inside the speaker it was converted back to DC. Energy losses can be expected here. A Customised amplifier running on DC only would be more efficient.

Nevertheless, we managed to sustain sound pressure levels around 96 dB (1m from speakers) for several minutes. (Hence the set-up in a sound-proof studio) See it in action here.

Discernible increases of load on the pedal whenever lower frequency audio was present (when “the bass kicked in”) show the clear need for buffering.

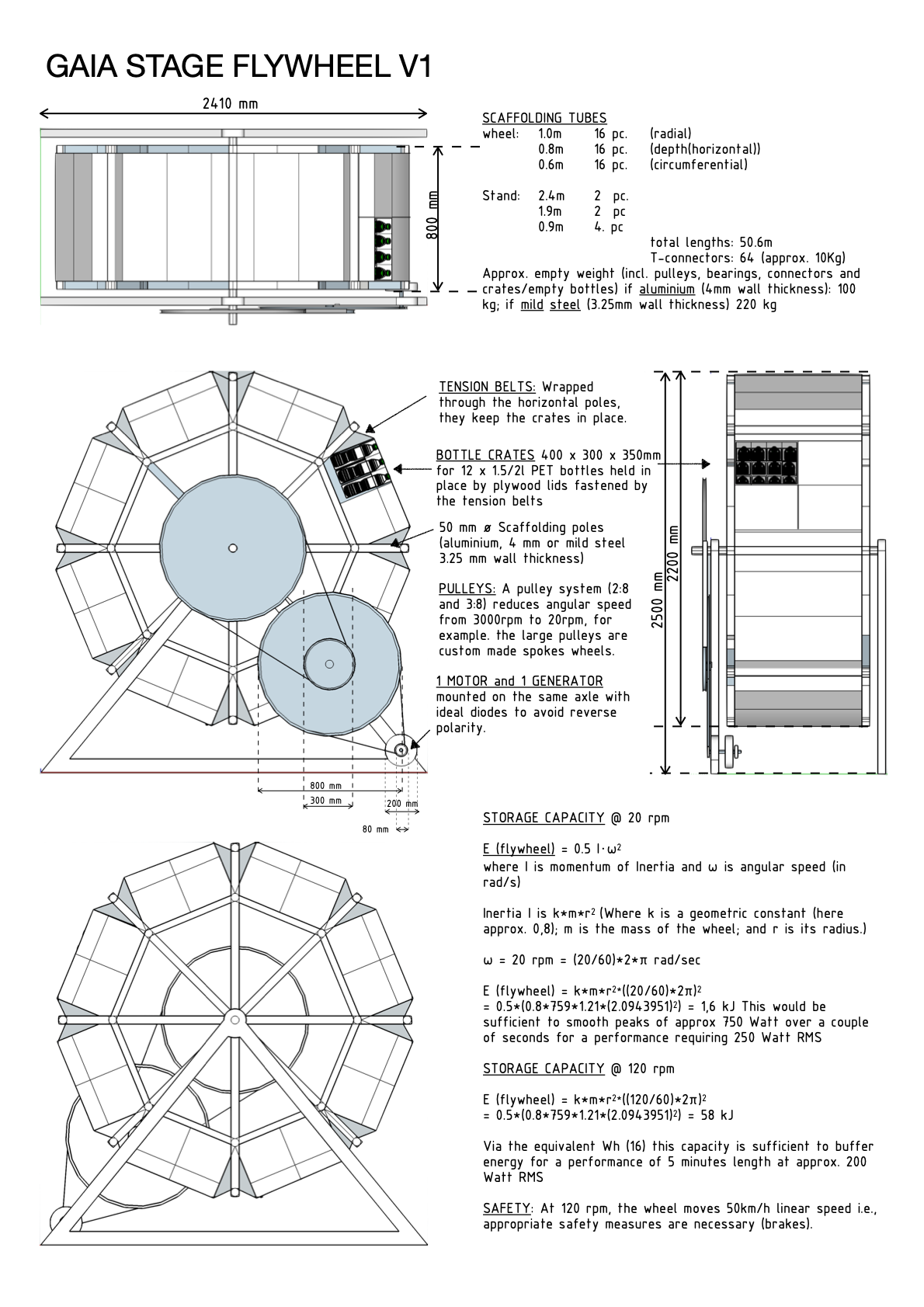

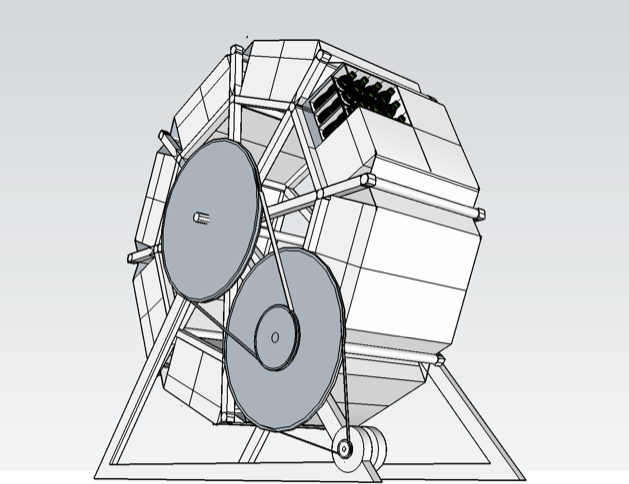

With the use of a flywheel instead of chemical batteries we react to the inherent environmental problems with chemical batteries: The high demands on rare earths in their production, their weight, their limited life-cycles and impact as hazardous wage, is contrasted here demonstratively to a sustainable technology which goes back thousands of years, using basic mechanical properties.

A flywheel's storage capacity increases with speed, weight and size. I order to keep the stage safe, we compromise on speed, and opt for a heavy, large but slow wheel: A system of pulleys transfers the energy back to high speed needed for the generator.

Even though a heavy flywheel seems counter intuitive to sustainability, by making it water filled, we thematise another use of resources: The water shall be sourced from lakes, rivers or the sea, and returned there, unaltered. The water is held in recycled PET drinking water bottles in standard bottle crates fixed to the wheel. Such a wheel of 2.2m diameter weighs 700 Kg, and can store energy for approx. 5 minutes of audio performance when turning twice per second (2Hz). After a performance, the empty bottles, plastic crates and the dismantled scaffolding fit on a small car trailer. The dismantled wheel weighs under 100 kg.

A series of systems decisions had to be made: Firstly, we customise standard AC equipment to DC as off-the-shelf 230V audio amplifiers and LED lamps internally convert back to DC anyway. DC at low voltages, needs heavy, large-diameter cables. To minimise this problem, we use multichannel amplifiers feeding passive speakers and we keep the distances from the generators to the amp(s) as short as possible. Audio signals themselves are AC, distribution from the amps to the speakers can be done in thin, standard audio cables.

We decided on brushless motor/generators (BLDC), as they are maintenance free and typically >90 % efficient. Brushed motors used to be a preferred choice for pedal generators as they run better on lower revs. But the recent rise in popularity of electric scooters means that also low-rev 24V BLDC are readily available.

In our set-up, we will have individual generators for each bicycle station, which can provide up to 250W (typically 100W). The power is then converted back to kinetic energy by a larger generator turning the flywheel. A third generator in line converts back to electricity for the stage.

In an ideal world, we could transmit the power from the bicycles to the flywheel mechanically, via universal joints and freewheel mechanisms to desynchronise the separate bike-stations. But the engineering demands are high and it is hard to implement with recycled materials. The summed loss over 3 universal motors (from bike to flywheel, and back to stage) due to internal resistances means that from 100 Watts supplied by 1 cyclist, 72.9 W go to the stage. (With brushed motors, this would be as little as 42W.) Further, we plan to additionally connect solar power cells and some wind-generators to the flywheel, in order to have electricity available in down-time, breaks, and before and after the events.